Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

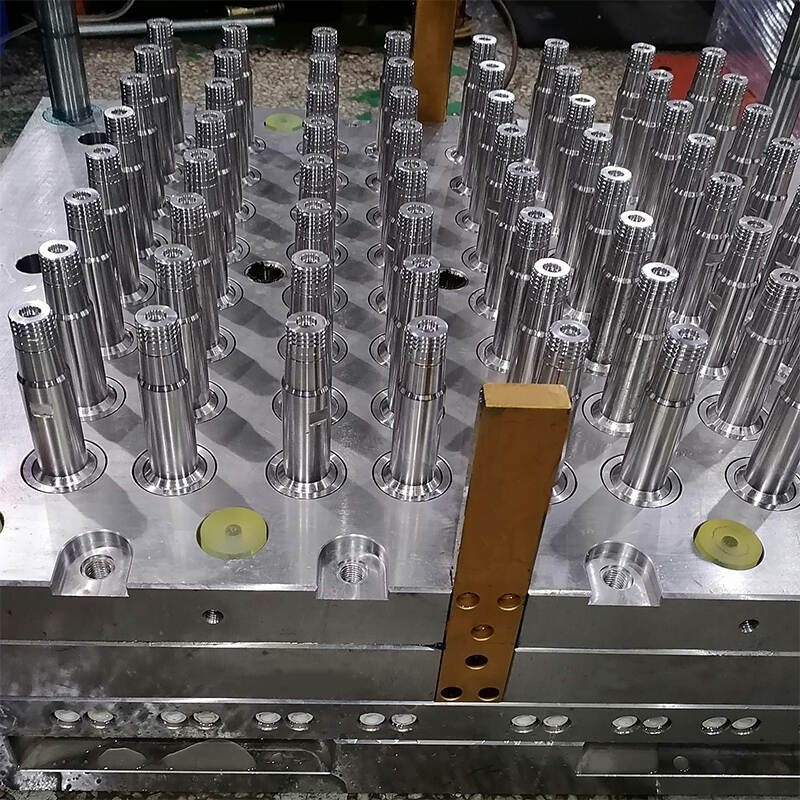

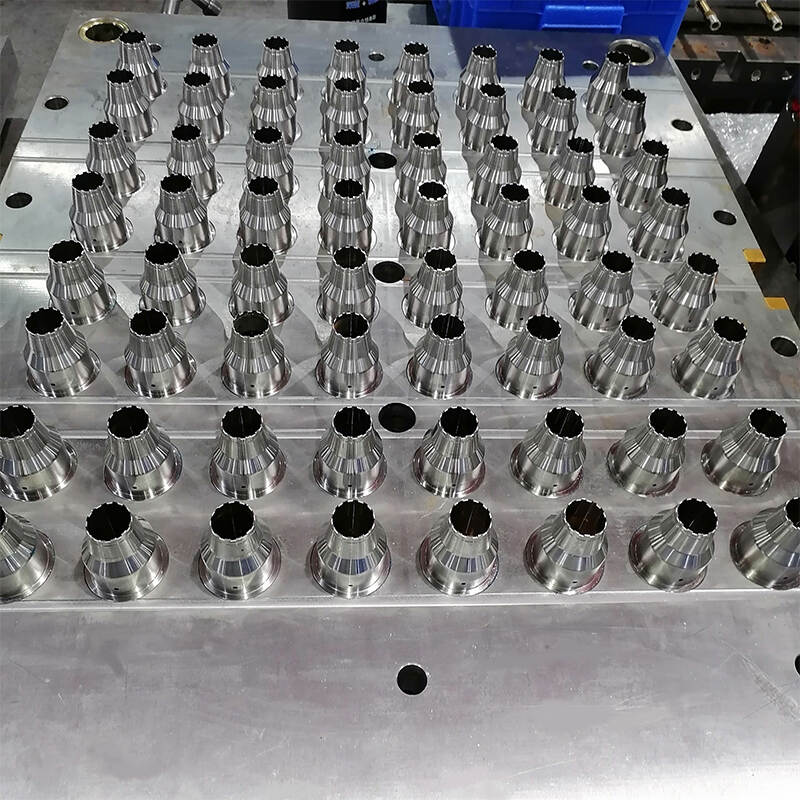

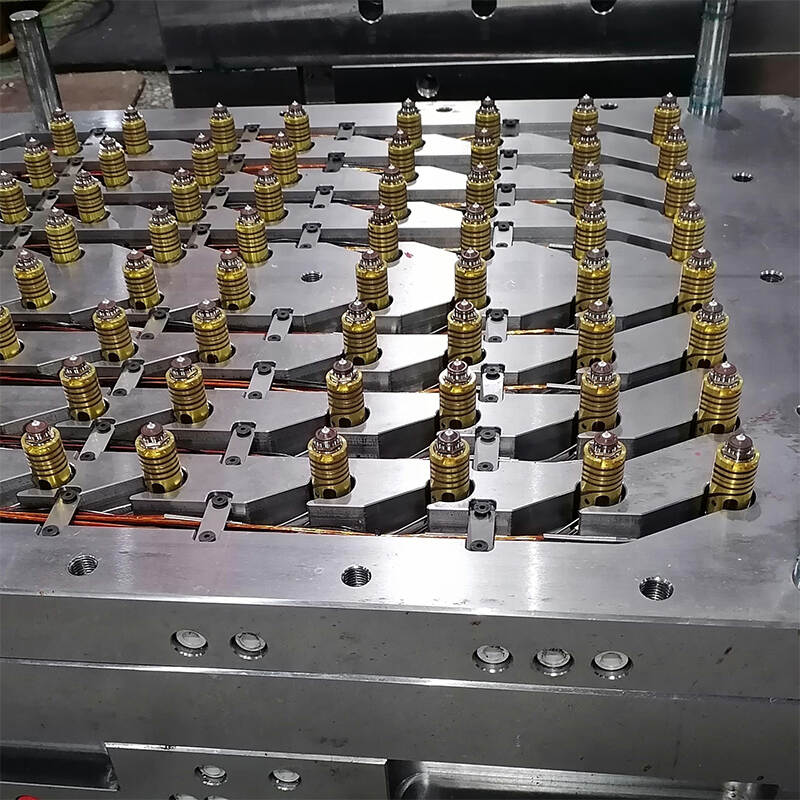

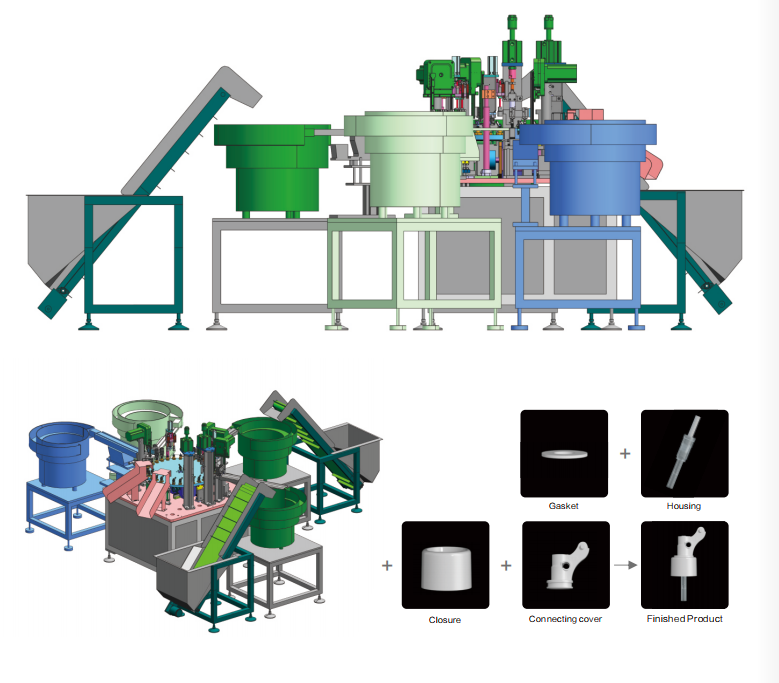

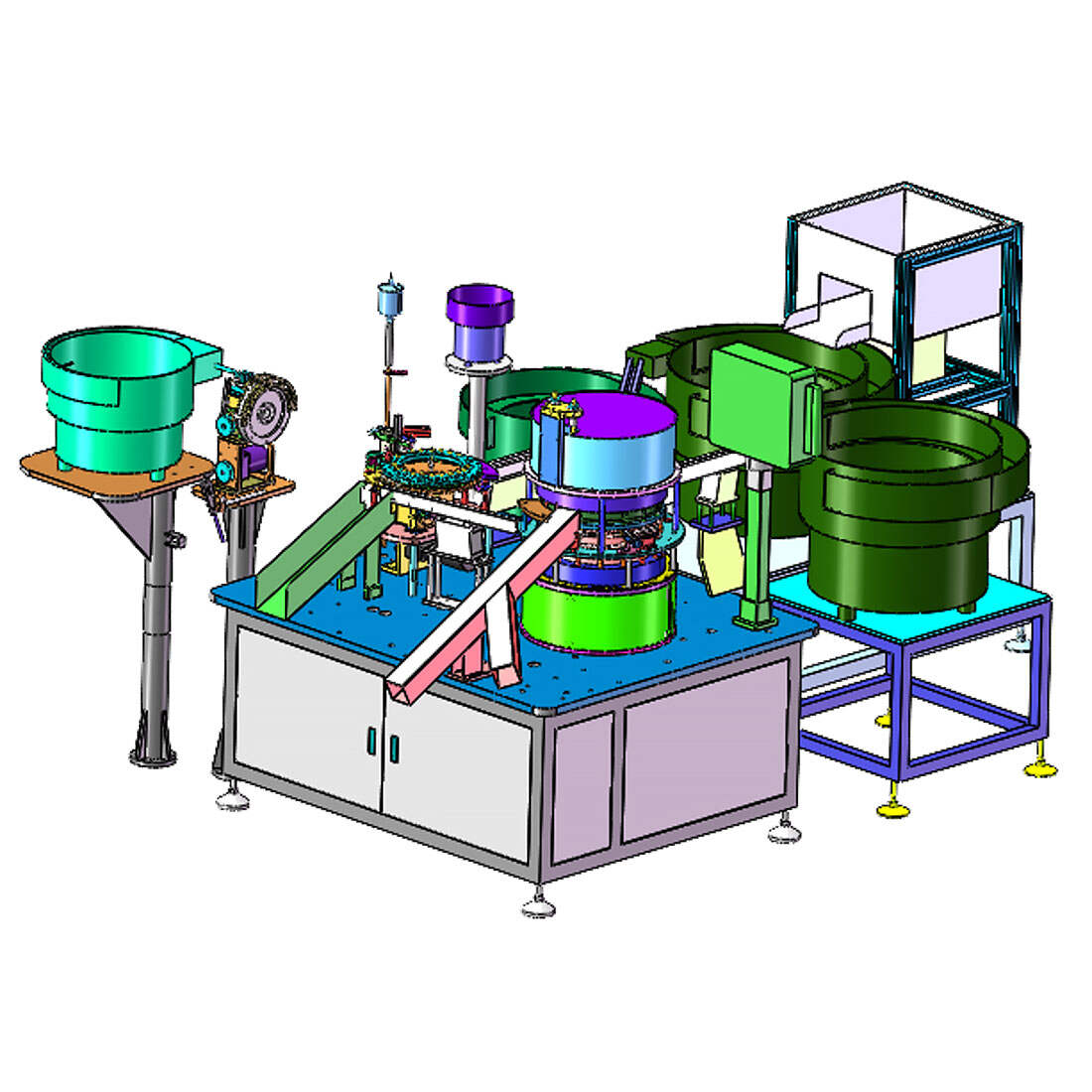

Foam Pump Injection Mould

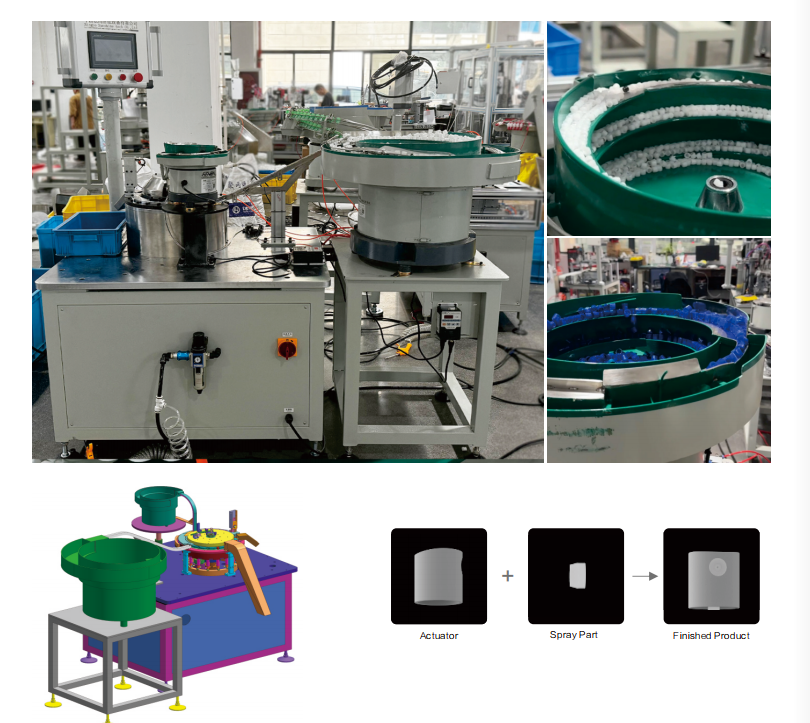

The foam pump injection mold is a precision-engineered tool designed for the efficient production of foam pump dispensers. Crafted with meticulous attention to detail, this mold ensures consistency, durability, and high performance in manufacturing processes. With its advanced design and premium materials, it caters to diverse industrial needs, promising seamless functionality and optimal results.

Description

Crafted by skilled artisans, the foam pump injection mold embodies precision and reliability. It facilitates the production of foam pump dispensers with exceptional accuracy and consistency. The Foam Pump Injection Mould is meticulously engineered to accommodate various specifications and requirements, ensuring seamless integration into production lines. From its robust construction to its refined finish, every aspect of the mold reflects unparalleled quality and craftsmanship.

Foam Pump Injection Mould Product Specification

|

Birthplace |

Ningbo, Zhejiang, China |

|

Brand |

Songrock |

|

Product Material |

Steel |

|

Plastic Material |

PP/PE/PET (all plastics) |

|

Product |

Designed and developed according to customers' requirements |

|

Regular-size frame |

45# steel, 50# steel |

|

Mould cavity |

S136, H13, and others according to mold product characteristics |

|

Mould surface |

Polished or sprayed with anti-rust paint according to the customer's requirements |

|

Mold heat treatment |

Cavity sleeve |

|

Mould Life |

Guarantee 100w mold |

|

Design Software |

UG |

|

Packing and shipping |

Packed in a wooden case for export, export molds coated with rust inhibitor, spare parts shipped with molds. |

Foam Pump Injection Mould Product Features and Advantages

1. Premium Material Composition: Constructed from high-quality steel, including 45# steel and 50# steel, the mold ensures superior strength and durability, enabling prolonged usage without compromising on performance.

2. Versatile Design: With a range of mold cavity options, such as S136 and H13, the mold caters to diverse production needs, accommodating various product designs and specifications with ease.

3. Customization Flexibility: Designed and developed according to customers' requirements, the mold offers unparalleled customization options, allowing for the creation of foam pump dispensers tailored to specific preferences and industry standards.

4. Enhanced Surface Finish: The mold surface is meticulously polished or sprayed with antirust paint as per the customer's requirements, ensuring a smooth finish and corrosion resistance, thereby extending its lifespan and maintaining aesthetic appeal.

5. Optimized Heat Treatment: Featuring cavity sleeve heat treatment, the mold exhibits enhanced thermal stability, minimizing wear and tear while ensuring consistent performance even under challenging operating conditions.

6. Longevity Assurance: With a guaranteed 103-watt mold life, the foam pump injection mold delivers long-term reliability, reducing maintenance costs and downtime, thereby maximizing productivity and profitability.

7. Efficient Packaging and Shipping: Packed in wooden cases for export, the mold is securely protected during transit, with additional measures such as rust inhibitor coating for export molds and spare parts shipped alongside for added convenience and peace of mind.

Benefits

- Timely Delivery: Standard products are shipped within approximately 60 days, ensuring prompt delivery to customers.

- Secure Packaging: Products are carefully packaged using aluminum-plastic bags, desiccant packaging, and wooden boxes, which provide protection against damage during transit and storage.

- Professionally Managed After-Sales Service: As a factory specializing in equipment and mold production, the company's after-sales service is managed by a team of professionals with expertise in their respective fields. This ensures that customers receive high-quality support and assistance tailored to their specific needs and requirements.